Compact, robust, and powerful: This characterises the TORNADO® rotary lobe pumps from NETZSCH Pumps & Systems. The self-priming and valveless rotary lobe pumps are particularly powerful and require little space due to their compact design.

As the global specialist in complex fluid management, NETZSCH also has various designs of rotary lobe pumps in its portfolio. We show you how to benefit from using a rotary lobe pump in multiple applications.

Customised Consulting

Get a personalized consultation!contact now

This is how a rotary lobe pump works

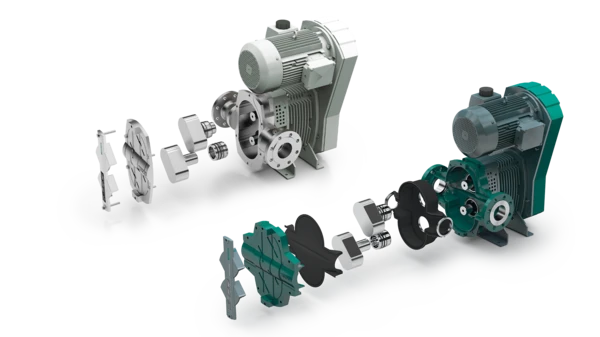

Rotary lobe pumps belong to the rotary positive displacement pumps group and are self-priming and valveless. They consist of a pump housing and two intermeshing lobe rotors. The rotation of the rotors creates a vacuum on the suction side, which draws in the pumped medium. The medium is driven into the pressure range by the rotors. This displaces between two and six space fillings per revolution, depending on the number of rotor blades. Therefore, a rotary lobe pump can also be used for speed-proportional dosing. A TORNADO® rotary lobe pump from NETZSCH also offers maximum operational reliability due to the worldwide unique separation between the pump and gear chambers. With rotary lobe pumps, you can convey low- and high-viscosity media without problems. Due to the significant free ball passage and low speeds, they are insensitive to blockages, clogging and foreign material. Varying solid contents do not affect the flow rate, nor do pressure changes. This enables you to achieve continuous as well as robust conveying and metering.

The TORNADO® T1 rotary lobe pumps convince with the GSS technology, a spatial separation between the pump chamber and gear box.

These are the advantages of a rotary lobe pump from NETZSCH

In addition to the unique spatial separation of the pump and gearbox areas already described, the FSIP® (Full Service in Place) design allows you to reduce service times and costs. This pays off quickly, especially in particularly wear-intensive applications. Thanks to the innovative design, service and maintenance can be carried out without removing the pump from the pipeline. It also gives you quick and easy access to the lobe rotors and shaft sealing. The material reversal also makes the TORNADO® rotary lobe pump particularly robust and durable. Another advantage of a rotary lobe pump from NETZSCH is the oil-free belt drive. It replaces the frequently used synchronous gear and is completely maintenance-free. For hygienic applications, we also offer rotary lobe pumps that are CIP (Cleaning-In-Place) capable. This enables you to clean in a circular or continuous process without prior dismantling from the plant. Rotary lobe pumps are also available in a mobile version. The mobility allows large liquids containing solids, wastewater, and sludge to be pumped in the most diverse and unusual locations. Depending on the application, the TORNADO® rotary lobe pump is mounted on a trailer with a diesel power unit in the appropriate size.

Benefit from a rotary lobe pump in these applications

From wastewater treatment to food-grade pumping of cacao liquor, the range of applications for a rotary lobe pump is enormous and varied. When pumping industrial wastewater, the rotary lobe pump impresses, among other things, with its robustness and ease of servicing. The TORNADO® rotary lobe pump reduces the downtimes of your plants and minimises the maintenance effort. For example, the mining industry also uses rotary lobe pumps to pump molybdenum slurry. The pump system is not only convincing due to the reduced service effort but, above all, due to its long service life. These properties are also increasingly in demand in the battery sector. In battery production, the pumps are suitable for pumping viscous slurries and liquids with a high solids content. On the other hand, the requirements in the food or pharmaceutical sectors are entirely different. Here, the TORNADO® rotary lobe pump guarantees high operational reliability due to its unique design. An essential element is that the pump chamber, lobe rotor and seals are free of dead space and flow-optimized. This means nothing stands in the way of hygienic and virtually maintenance-free pumping. All areas of application of a TORNADO® rotary lobe pump:

- Environment & Energy

- Food & Pharmaceuticals

- Battery

- Mining

- Oil & Gas Mid- / Downstream

- Chemical, Pulp & Paper

Portfolio of rotary lobe pumps from NETZSCH

The rotary lobe pump portfolio at NETZSCH includes six different versions. These include variants for industrial use, pumps for conveying foodstuffs or chemicals, and mobile versions. Depending on the individual application, we select the suitable model for you. All versions at a glance:

- TORNADO® T.Envi® Rotary Lobe Pump

- TORNADO® T1 Rotary Lobe Pump

- TORNADO® Mobile

- TORNADO® T.Proc® Rotary Lobe Pump

- TORNADO® T.Sano® All-Metal Rotary Lobe Pump

- TORNADO® T.Sano® Rotary Lobe Pump With Smooth Surface

In addition to the rotary lobe pump technology, NETZSCH offers numerous other positive displacement pumps such as NEMO® progressing cavity pumps, NOTOS® multi screw pumps or PERIPRO peristaltic pumps grinding systems and barrel emptying systems are also part of the portfolio of the global specialist in complex fluid management. Let our experts advise you – together, we will find the right solution for your application.