IN a significant development for the mining industry, Schurco Slurry, a leading heavy-duty centrifugal slurry pump manufacturer, has successfully supplied 20 new pumps to a copper mine in the Northern Cape.

This milestone is accompanied by a substantial order of spares valued at over R600 000 from a prominent copper company in Zambia.

The products provided are set to play a crucial role in enhancing the operations of both clients, spanning copper processing and tailings facilities management.

Schurco Slurry’s success can be attributed to its commitment to innovation and high-quality materials. The recent surge in demand in Zambia has prompted the company’s local supplier to maintain a substantial stock of various components, reflecting the industry’s growing reliance on Schurco Slurry’s offerings.

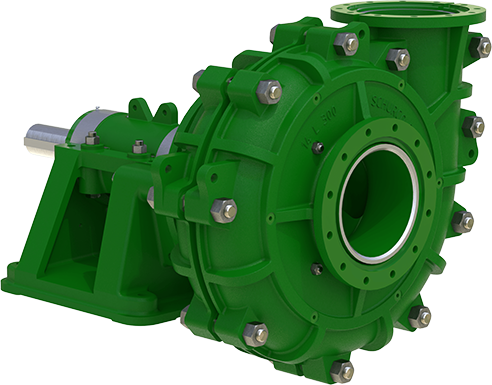

The supplied equipment, including pumps, liners, impellers, and other spares, is tailored for the harsh and corrosive environments encountered in copper processing. Notably, Schurco Slurry specialises in the use of polyurethane, a proven material known for its exceptional resistance to corrosion and abrasion.

The wet-end spares are manufactured from Schurco Slurry’s proprietary polyurethane compound, boasting a wear life approximately 66% longer than alternative linings available on the market.

The manufacturing and research processes take place at Schurco Slurry’s state-of-the-art facilities in the US and South Africa.

Marc Young, Schurco Slurry Pump applications and projects manager, emphasises the company’s dedication to addressing the challenges posed by variable minerals processing. He notes that Schurco’s slurry pumps are customised for each mine and application, ensuring optimal performance and longevity.

The South African branch, located in Johannesburg, and the US holding company maintain extensive stocks to meet the demands of global markets.

In addition to serving clients in Zambia and the Northern Cape, Schurco Slurry supplies copper mines in the Democratic Republic of Congo, South America, and Eastern Europe.

The company is actively planning an expansion into African territories and has established an office in Dubai to cater to the Middle East and surrounding regions.

Polyurethane-Lined Slurry Pumps: An Industry Game-Changer

Polyurethane-lined slurry pumps have become a cornerstone in various industries, particularly in mining, mineral processing, and wastewater treatment. What sets these pumps apart are their exceptional attributes that contribute to enhanced efficiency, reduced maintenance costs, and a more sustainable industrial landscape.

Polyurethane-lined slurry pumps offer a myriad of advantages, including exceptional wear resistance, chemical compatibility for handling corrosive slurries, lightweight design for easy installation and maintenance, dampening properties for a safer working environment, high-efficiency impellers reducing energy consumption, modular designs for straightforward maintenance, easy customization for specific operational needs, abrasion-resistant linings prolonging component life, and environmental friendliness through recyclability and reduced emissions during manufacturing.

In conclusion, the success of Schurco Slurry in supplying polyurethane-lined pumps attests to the numerous advantages of this technology.

These pumps offer a compelling combination of wear resistance, chemical compatibility, durability, efficiency, and safety.

As industries continue to rely on the efficient transport of abrasive and corrosive materials, polyurethane-lined slurry pumps stand out as indispensable assets, contributing to a more sustainable and efficient future.