Fire presents many challenges, not least because of the variables that determine which suppression medium is appropriate for a given fire situation. Our objective in this two-part article is to provide guidance based on a hazard-specific approach and help you make an informed decision on appropriate fire-suppression measures, especially with regard to the processing and storage of flammable liquids.

Fire hazards are classified as follows:

- Class A – carbonaceous or combustible materials

- Class B – flammable liquids

- Class C – flammable gases

- Class D – metals such as magnesium

- Class F – fires generally associated with cooking such as vegetable oils

- Class E – electrical hazards.

As a manufacturer of foam proportioners and firefighting monitors, we specialise mainly in the Class B category: flammable liquids.

Foam is considered to be the most effective fire-extinguishing medium for both hydrocarbons and polar solvents. In addition, certain types of foam (known as wetting agents) are specifically for deep-seated Class A fires where water only may not penetrate the fire load effectively.

How do we make foam?

Finished foam solution comprises a simple recipe of foam concentrate, water and air. Foam concentrate is typically mixed in the ratio of 1% or 3% to either 99% or 97% water.

Once the solution (premix) is created, it is pumped to the chosen discharge device – we will cover proportioning later in this article and discharge methods in Part 2. At this point air is entrained by using devices designed to naturally aspirate the solution. The amount of aspiration and the type of concentrate determines the expansion ratio. This is typically split between low, medium and high expansion. Low expansion is up to 20:1, medium is 200:1 and high expansion is more than 200:1. Only high-expansion foam may need the addition of a water-driven generator fan to expand the foam adequately, although naturally aspirated generators are also used. The decision to choose a particular expansion ratio is determined by the hazard under review.

Put simply, water and oil do not mix. Applying only water to Class B products will not suppress the burning vapours. This is an important point to make as it is the vapours, not the liquid itself, that burns. We need a medium that allows for the formation of a vapour-suppressing and oxygen-depleting blanket and/or a barrier film to be successful. Whatever method is chosen to produce that blanket or film, the objective is the same.

A little of the history of foam development

We can date the development of modern foam concentrates from the 1960s onwards. Up to that point foam concentrates were comprised of animal-based protein (typically ground hoof and horn is the base component). The main drawback was due to limited fuel tolerance, which meant it was susceptible to fuel pick-up (mixing). A breakthrough came with aqueous film-forming foams or AFFF’s. Instead of using protein as the base product, synthetic detergents gave foam a greater fuel tolerance as well as forming a vapour-sealing film across the surface of the fuel. Performance is further enhanced with the formation of a foam blanket when air aspirating devices are fitted.

Nevertheless, AFFF’s development did not completely replace the use of protein-based foam. Fluoroprotein, or FP, meant that protein foam could both combat fuel pick-up (mixing) and offer a good resistance to heat, defined by the industry as ‘burn-back resistance’.

Further development in the 1980s took FP to the next level with film-forming fluoroprotein or FFFP. We now had the best of both worlds: a film-forming foam that also had good burn-back resistance.

The 1980s further added to our list of acronyms with FFFP-AR – film-forming fluoroprotein, alcohol resistant. Alcohols or polar solvents had always presented an additional challenge as they were water soluble and foam destructive. The FFFP-AR chemistry included a polymeric barrier, which protected the foam blanket from early destruction. The same technology also became available with the new generation of AFFF-ARs.

In recent years fluorine, one of the cornerstone ingredients to all foams, has become an environmental issue, due to persistence in groundwater. The industry has been presented with a major challenge to eliminate the ‘fluoro’ element of all the different foam concentrate types. We have witnessed an era of manufacturers’ claims and counter claims regarding the efficacy of a whole range of newly formulated fluorine-free foam. The term ‘SFFF’ (synthetic fluorine free foam) or ‘F3’ is used to define these foams, which have become the new normal and first choice for operators changing existing stock or reviewing new projects. As a foam proportioner manufacturer we must examine the physical properties of foam carefully (especially viscosity) as they influence decisions on the overall proportioning solution. More of this later.

Multi-purpose foams such as the F3 alcohol-resistant types are increasingly important in the fuel-storage arena. The introduction of E10 petroleum, with its 10% ethanol-based biofuel content, means that the alcohol-resistant quality of SFFF/F3 is necessary to combat the small degree of water miscibility of the fuel.

All foam concentrate manufacturers will naturally promote their product as being highly effective. The best way of comparing their claims is to familiarise yourself with the empirically based standard EN 1568 or UL162. The tests cover extinction time, foam stability (via drainage time tests) and post-fire security (burn-back test). Hydrocarbons and the more demanding polar solvents are both included in the test protocols. This also covers fresh and seawater as well as gentle and forceful application of the foam. Each foam is given a rating with IA being the best, IIID the worst. This means that you can challenge foam suppliers in order to make an informed decision on the best foam for your needs.

Whilst EN 1568 is an excellent benchmark standard, awareness of the effects on foam performance from factors outside the standard tests should be noted. For example, particularly aggressive solvents can challenge the firefighting effectiveness of certain foams. This can be exacerbated by different ambient air temperatures, the application method, fuel depth etc. Our advice would be to understand the details of the tests and try to match them to the foam’s appropriateness for your individual hazards. We would always recommend consulting individual foam manufacturers as they can often provide specific in-house fire-performance data against some of the more unusual fuels.

However, despite the foam manufacturers’ sometimes conflicting claims on performance, the earlier fundamentals of how foam is proportioned still remain: 1% & 3% concentrates are the norm for producing a finished foam.

Critical factors for success: the time and application rate matrix

Successful extinction of flammable liquid fires depends on two converging and complementary factors: time and the rate at which finished foam is applied. Both are determined by empirically based standards published by bodies such as the National Fire Protection Association (NFPA) in the United States and in Europe by the EN standards.

The ‘time’ factor means that for a given size of fire area it is necessary to apply the foam for long enough to achieve extinction and to prevent re-ignition. This is especially critical in manual intervention as firefighter’s will be at risk during post-fire operations. When it comes to fixed protection for hydrocarbon and polar solvent tanks, the application time can be as long as 60 minutes for the largest tank diameters.

The application rate refers to the amount of finished foam applied per square metre. This varies according to the fuel and the foam type but is currently no less than 4.0 litres per minute per square metre. One of the ongoing developments in foam performance is the likelihood that this will be reduced, but standards often take time to recognise product development. Anything less than the minimum application rate means that fire control is unlikely to be achieved. This means that firefighting resources, particularly in a manual fire attack, need to be assembled before firefighting commences and this takes time. The advantage in fitting fixed systems is that the resources are already designed and built into the system for immediate application.

Foam proportioning methods: mixing water with foam concentrate

In order to allow readers to make an informed decision on how best to tackle their particular fire challenges, the following is an overview of the various foam proportioning methods.

Foam inductors:

Typically associated with fire service deployment and limited fixed systems applications. This uses the venturi principle to create a pressure drop in a small aluminium or seawater material compatible device with built-in concentrate pick-up tube. The pressure drop created by the venturi draws the foam concentrate from a container where it mixes with water to create foam solution. Both the pick-up tube and body of the inductor are compact enough to be easily carried on a fire appliance or fitted into a pipework system.

However, whilst it is considered to be the simplest method, it has severe drawbacks: (i) units are factory calibrated so any changes to the hydraulics (caused by length of discharge line after the inductor, the elevation of the discharge device or a changing quantity of discharge devices) will likely require a system re-design; (ii) system design and sign-off are critical as deviations caused by pipe diameter changes will adversely affect proportioning accuracy and potentially prevent any proportioning; (iii) changes in concentrate viscosity will undermine the ability of the venturi to draw concentrate into the downstream lines; (iv) pressure loss is high, as much as 35%, so duty pump pressures need to be high enough to allow for it, potentially adding additional cost into the system; (v) foam delivery devices need to be sized so as not to restrict design flows; (vi) testing cannot be achieved without creating premix and discharging finished foam. This will add to whole lifetime costs as a result of foam concentrate usage, which has to be replaced, and the disposal of premix or foam.

Balanced pressure proportioners:

These use an electric or a combination of electric and diesel pumps to supply foam concentrate into a proportioner at a higher pressure than the incoming water-line pressure. The proportioner is installed into the water line and regulates the mixing.

They are now associated with older systems, where disadvantages include: (i) additional costs in hardware and design time; (ii) the foam pump is normally restricted to a much tighter operating range, although the proportioner itself can accommodate wide ranges in flows; (iii) the foam pump needs an additional power source, other than water, so is not as reliably secure as a system with a potential single point of failure, such as an entirely water-driven system; (iv) typically, these systems are very complex and cause high efforts at the customer with set-up, commissioning and testing; (v) the recirculation of unused foam concentrate creates unnecessary agitation that has the potential to damage the foam concentrate and entrain air, which in turn can undermine accurate foam proportioning and foam extinguishing effectiveness.

Bladder tanks:

Comprised of a steel pressure vessel containing a flexible bladder (typically a butyl material) linked to a foam concentrate proportioner similar to the ones fitted to balanced pressure proportioners. The incoming pressurised water compresses the foam filled bladder so that foam concentrate can be proportioned with water using the same supply. The venturi principle is again brought into play as it creates a pressure drop at the point of injection for the foam concentrate. Testing cannot be achieved without creating premix and discharging finished foam. This will add to whole lifetime costs as a result of foam concentrate usage, which has to be replaced, and the disposal of premix or foam.

However, the bladder itself is seen as a weakness because great care is needed to avoid a damaged bladder when commissioning a new installation. It is never easy to work within the steel pressure vessel should problems occur, especially if and when a replacement bladder may be required: it all adds to the difficulty and cost.

Compressed air foam (CAFS):

This is not a proportioning method in the conventional sense as the foam is already proportioned using one of the previous methods. However, pressurised air is then added forcefully rather than naturally entrained or aspirated. As the name suggests, CAFS injects compressed air into the foam solution at the point of discharge. The consensus view is that CAFS enhances the finished foam’s ability to cling to vertical surfaces allowing better penetration and cooling. This is also a benefit in wildfire situations by coating vulnerable structures to mitigate fire growth. The limited water supplies associated with remote wildfire areas means that the resource can be fully optimised. However, as with balanced pressure proportioner foam pumps, an additional point of failure is possible due to the additional CAFS apparatus.

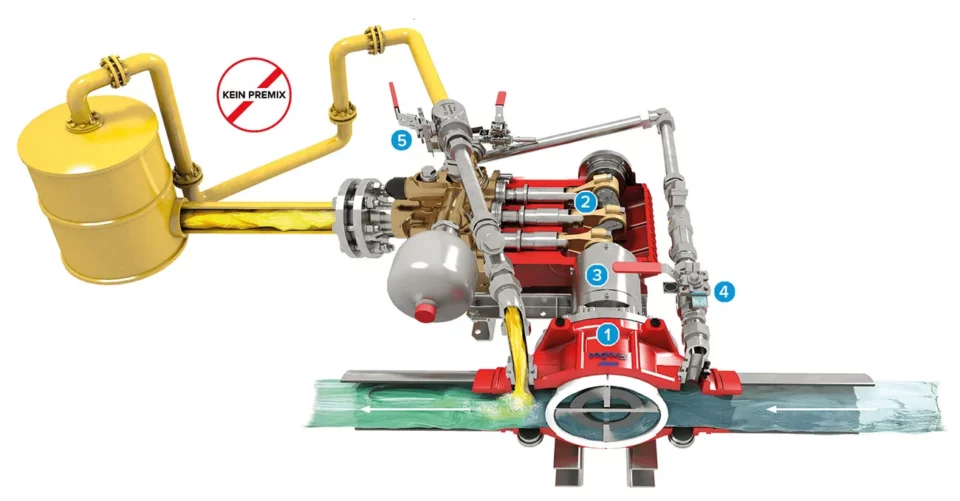

Water driven or turbine foam proportioners:

FireDos have become synonymous with their unique water-driven foam proportioner. Now in its third generation, the product is purely mechanical and highly reliable. A water-driven rotor supplies the motive force to drive a directly coupled positive-displacement plunger or piston pump. This is supplied with foam concentrate via an atmospheric foam tank adjacent to the FireDos unit. The proportioning pump is factory set to the required proportioning rate and will proportion the foam concentrate accurately across a wide operating range. The purely mechanical system provides cost-efficient and eco-friendly proportioning rate testing, completely without using any foam concentrate or creating premix or firefighting foam.

The benefits of FireDos Gen III FM approved foam proportioners include:

- Reduced costs: proportioning rate is tested without using foam or creating premix or foam – cost effective and eco-friendly.

- Improved performance: constant proportioning rate across a wide operating range.

- Optimised delivery of high-viscosity foam concentrates with improved suction capacity.

- 25% reduction in pressure loss, compared to older generations, through hydraulic optimisation.

- Improved cylinder cut-off for easy and fast adjustment to a different proportioning rate.

- FM approved FireDos Gen III proportioners are to date the only FM approved water motor coupled variable proportioners utilizing FM approved flow meters. Using the test return line this offers the possibility to check the proportioning rate during commissioning as well as for annual tests, without creating any premix, which is a very big benefit for the user and relieves the environment.

In the second part of this feature we will explore the effects of viscosity on foam proportioning and typical foam application areas and recommended discharge devices.

For more information, go to www.firedos.com

Written by

David Owen